Agricultural tyres: switching from words to numbers – Interview of Agostino Provana

Agostino Provana has been a leading name in the agricultural sector for over 40 years, offering comprehensive solutions for fleets and contractors, as well as technical consulting to help tractor and tire manufacturers optimize the performance of their products.

The Provana Group testing center, located in Izano (CR), has evolved over time with the construction of a track and a training center, but above all with the introduction of advanced digital testing technologies. The main current goal is to move from subjective to objective testing, thanks to the possibility to obtain measurable data.

We met Agostino Provana at the Field Day organized by Yokohama-ATG in early October, designed to demonstrate to customers and the press the impact of tire pressure and the Alliance’s advanced technologies on efficiency, fuel consumption, and sustainable agricultural practices.

What tools give the possibility to move from subjective to objective testing?

Our extensive experience in testing and market tests with fleets and contractors has taught us how crucial digital technology is to providing objective and effective results, both from a technical and commercial perspective.

Encoder connections and the introduction of a flow meter have facilitated the organization of a database that collects real-world data on traction, comfort, handling, average life, and actual fuel consumption, broken down by brand and terrain type (road or field).

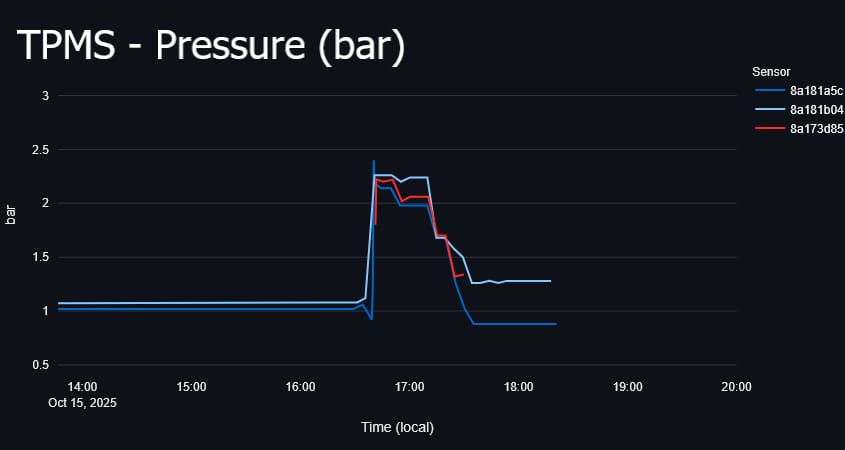

Over the course of the year, we took a further step forward by introducing sensors connected to the vehicle’s CAN bus, allowing us to directly acquire data and develop algorithms capable of suggesting optimal tire pressure based on the type of usage.

What concrete benefits does this bring for fleets and contractors?

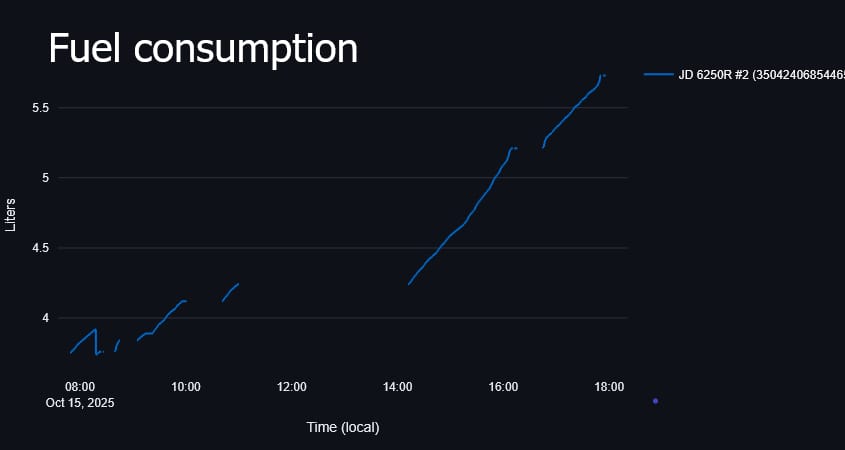

This data translates into effective fuel savings, simply by adjusting the tractor’s timing and adapting the pressure based on the type of terrain.

We have also launched an innovative service for some fleets and contractors: the hourly cost tire supply, with remote maintenance via diagnostic software that continuously monitors pressure and temperature in real time.

Is the Alliance Field Day part of this process of “performance objectification”?

Exactly. The event was organized by Yokohama-ATG to present new Alliance products, and they chose our facility specifically to bring the presentation to life. We conducted field and road demonstrations with different pressures, then we analyzed the collected data and translated it into fuel consumption.

This approach is significantly more effective, especially in a market where many agricultural tires are launched, but their proper use and impact on fuel consumption are often unknown.

How much do product choice and inflation pressure impact performance?

Every test confirms that differences in fuel consumption and performance depend both on the product and its use. Instinctive perception is always confirmed by the numbers: the same tire, if used incorrectly, does not deliver the expected results. It is therefore essential to seek advice and choose the product best suited to your needs.

How can a fleet or a contractor choose the right tire?

Manufacturers often offer two or three models for the same size, and the market tends to prioritize the brand over the tire model, without considering how much fuel a given tire might consume. For this reason, the Provana Group aims to be a point of reference: we can help the end customer choose the right product or, better yet, manage the entire tire service. We provide the most suitable tire, pre-mounted on the rim, at an hourly rate, and we take care of maintenance thanks to remote pressure and temperature monitoring.

And what do you offer to tractor manufacturers?

Our center should become—and is already becoming—a point of reference for them too. Thanks to the CAN bus, today a wealth of data is collected on tractor performance, but the tire’s environmental impact is still not considered. With our sensors, we can develop algorithms that demonstrate how tire choice can impact up to 6 liters of diesel fuel per hour. It’s therefore essential for manufacturers to take this data into account, especially when introducing new engines, whose performance can be compromised by unsuitable tires. An extreme example? Think of Formula 1 and how tire pressure can determine the outcome of a race.

Is it important for tire and tractor manufacturers to collaborate in development?

Absolutely—and I would add wheel manufacturers as well. When all the players communicate, truly effective solutions emerge. If everyone goes their own way, technical developments are more difficult to achieve.

Is there already a beginning of a collaboration?

I’d say so, even though we’re living through a challenging period, with some major historic tire brands exiting the agricultural sector. However, I sense a greater push toward innovation, because manufacturers know that without innovation, they risk being driven out of the market due to price pressures.

The Provana Group has already initiated collaborations with two tractor brands and several tire brands. We were delighted that Yokohama-ATG chose our facility for the Alliance event with press and customers: we believe it’s important to provide the market with objective, technical information.

Yokohama-ATG has begun to explain that price isn’t the crucial point: what matters is the overall operating cost, both in terms of fuel savings and emissions reduction. And that’s exactly where we need to get to: operating costs are the real indicator, and the differences don’t depend so much on the brand, but on the choice of the right solution and the way the tire is used.

(translation of the article on the following website: Pneusnews.it – Link)